Vulclast® / Scarf Jointed O-Rings

Making a jointed “O” ring may seem simple, but it is a precise and specific process to achieve a high-performance bond compatible with the extruded cord.

The concept:

Scarf jointed “O” rings have become an industry standard for static sealing applications, especially where non-standard diameters are required. The major benefit is that these rings can be made in almost any size without the need for expensive mould tooling. Making a jointed “O” ring may seem simple, but it is a precise and specific process to achieve a high-performance bond compatible with the extruded cord. The conventional method involves bringing the cut ends of the extruded cord together and using a solvent-based adhesive to create the bond.

Our manufacturing process:

At Eastern Seals, we manufacture our own range of high-quality hot vulcanized scarf jointed “O” rings for this diverse and demanding market. We have completed the development process and launched our Vulclast® range. Our bonding process provides a strong bond that matches the extruded cord, ensuring compatibility with the generic compound used and imparting similar physical properties and chemical resistance. The critical aspects of our manufacturing process include measuring the extruded cord, bonding, ensuring bond strength, finishing, and conducting final visual and dimensional inspections.

Hardness testing, Range 60 to 90 Shore

Conducting final visual and dimensional inspections

Inspection:

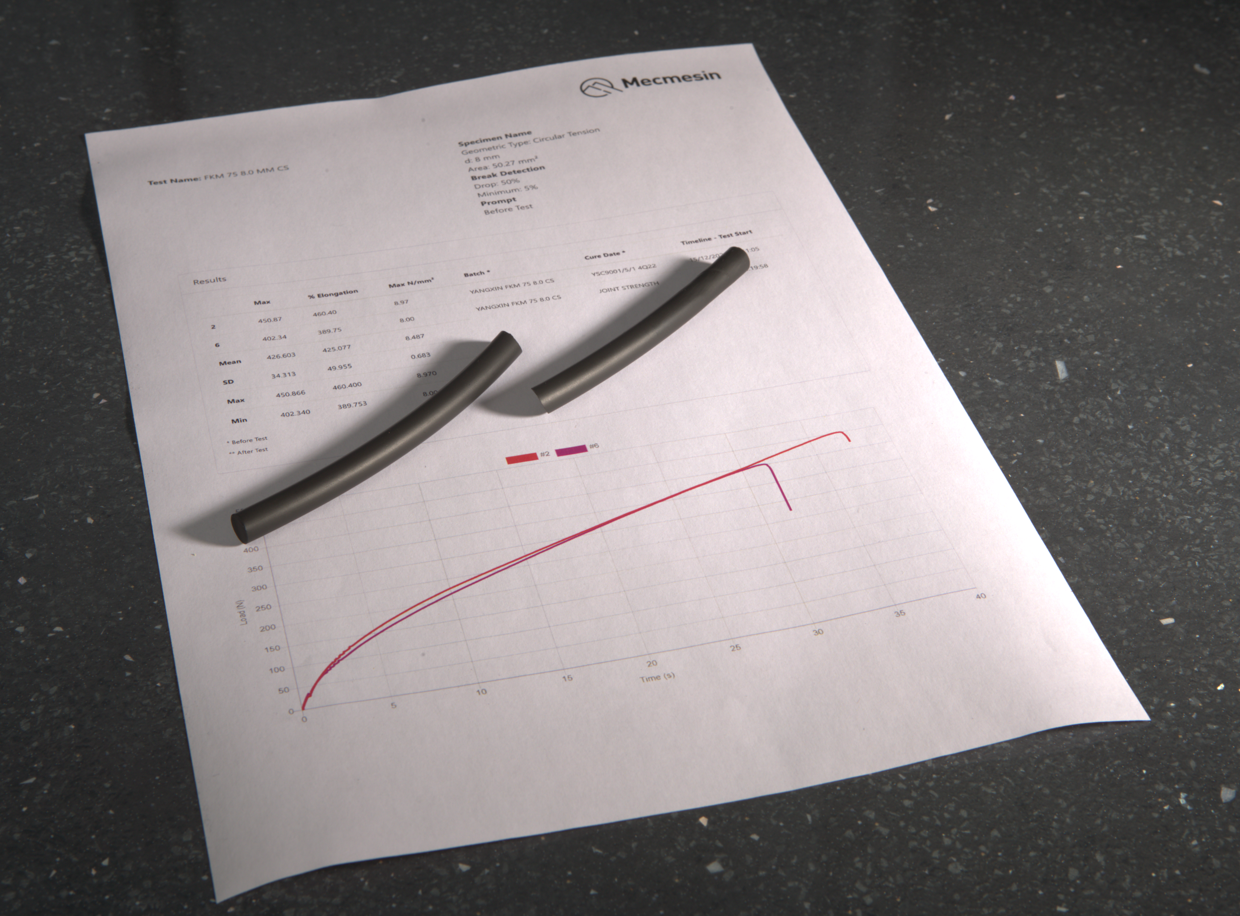

We carry out 100% visual inspection on all produced rings, examining them for abnormalities by slightly pulling and twisting the joint. Extreme bending of the joint is not recommended as it does not undergo such bending during use. Additionally, we sample check the bond integrity using a computer-controlled tensile tester to assess the strength of the base cord. Results are documented and reports can be provided to customers upon agreement.

Bond strength test reports

Assessing the strength of the base cord

Quality:

Achieving the highest quality of product is paramount to us. We have implemented a unique method to achieve dimensionally accurate finishes and tolerances around the bonded join area while adhering to ISO 3302-1 Class E1 standards. Sample checks are conducted on the inside diameter measurements of the ring’s, dependant on size, using modern camera technology to ensure compliance with current BS and ISO tolerances. For rings larger than the standard sizes, we apply an in-house tolerance based on the nominal diameter.

Main attributes of our Vulclast® range:

- Rapid manufacturing process

- Can be made to virtually any inside diameter without expensive tooling

- Cords available in a wide range of compounds with a cross-section range of 1.78 mm up to 16 mm and shore hardness range 60 to 90

- Extruded cord tolerances meet or exceed ISO 3302-1 Class E1

- High bond strength compared to the cord itself

- Joint interface compatible with the extruded cord

- In-house bond strength testing as part of our quality control

In addition to our unparalleled quality, we offer services that align with our commitment to being the premium supplier in the industry:

- Standard 2-3 day delivery service

- Hot Shot service (shipped within 24 hours of order receipt)

- Bond strength test reports available with certification upon agreement.

REQUEST A CALLBACK

If you have any queries, or would like any more information,

don’t hesitate to get in touch