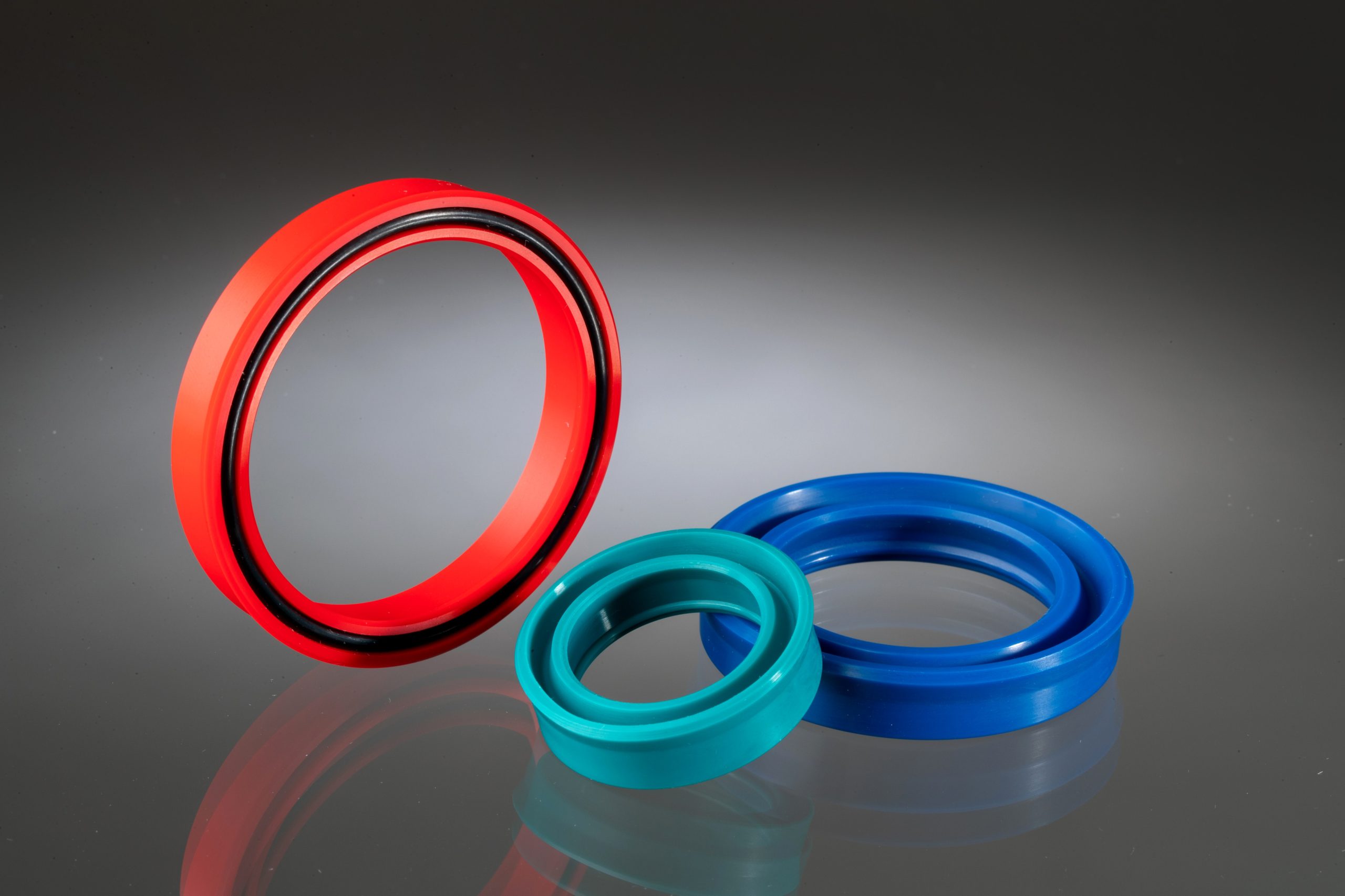

Hydraulic Seals

Hydraulic seals & Pneumatic seals are designed as per the cylinder working pressure, cylinder speed, operating temperature, working medium and application

Hydraulic Seals

Hydraulic seals are essential components in hydraulic systems, designed to prevent fluid leakage and maintain pressure within machinery. These seals are typically made from flexible, non-metallic materials and are carefully fitted into grooves or combined with other rings to form a seal assembly. Their primary function is to control the movement of fluid, ensuring it remains contained in applications involving reciprocating motion.

Hydraulic seals play a crucial role in converting fluid power into linear motion, making them indispensable in various types of machinery. They are crafted from materials such as polyurethane, rubber, or PTFE, selected based on the specific requirements of the operating environment. Factors like fluid type, pressure, chemical compatibility, and temperature all influence the choice of material.

There are two main types of hydraulic seals:

- Dynamic Hydraulic Seals: These seals are designed to handle movement and are further categorized based on their function within a hydraulic cylinder:

- Static Hydraulic Seals: These seals are positioned in a groove and do not experience any movement. Their role is to seal within a confined space, much like a gasket, providing reliable sealing without wear from motion.

Choosing the right hydraulic seal is critical to ensuring the efficiency and longevity of hydraulic systems, making them a key consideration in the design and maintenance of machinery.

Piston Seals

Hydraulic piston seals are components used in hydraulic systems to prevent fluid leakage and maintain proper pressure within the system. They are typically installed in the cylinder bore and provide a dynamic sealing solution between the reciprocating piston and the cylinder wall.

Click to Read More.Rod Seals

Hydraulic rod seals are critical components used in hydraulic systems to prevent leakage and maintain the integrity of the system. They are installed around the rod or shaft of a hydraulic cylinder and act as a barrier between the internal hydraulic fluid and the external environment.

Click to Read More.Wiper Seals

Hydraulic scraper seals, also known as wipers or scraper rings, are components used in hydraulic systems to protect the hydraulic cylinders from external contaminants such as dirt, dust, moisture, and debris. They are installed in the hydraulic cylinder to prevent these contaminants from entering the system and causing damage to the internal components.

Click to Read More.Wear Rings

Hydraulic guide rings, also known as wear rings or guide strips, are components used in hydraulic systems to provide axial or radial guidance to the moving components within the system. They are typically installed in cylinders, piston heads, or other moving parts to minimize friction, control motion, and improve overall system performance.

Click to Read MoreEastern Seals’ Hydraulic & Pneumatic range caters for the full range of duty cycles. Typical applications covered are cylinders, mobile cylinders, hydraulic presses and moulding machines.

We can supply seals for single and double acting cylinders, compact seals and composite piston seals, symmetrical seals, independent wear rings, bonded seals and static seals, such as O rings.

Part of our Hydraulic range includes telescopic seals.

Eastern Seals UK Ltd offer a range of seals especially suited to pneumatic applications. Our products are formulated to give optimum properties including, ultra long life, ultra low friction, water resistant and wide temperature capability.

REQUEST A CALLBACK

If you have any queries, or would like any more information,

don’t hesitate to get in touch

Online store

We are the largest supplier of British Standard, Metric series O-rings and sealing solutions.

Visit Store Now